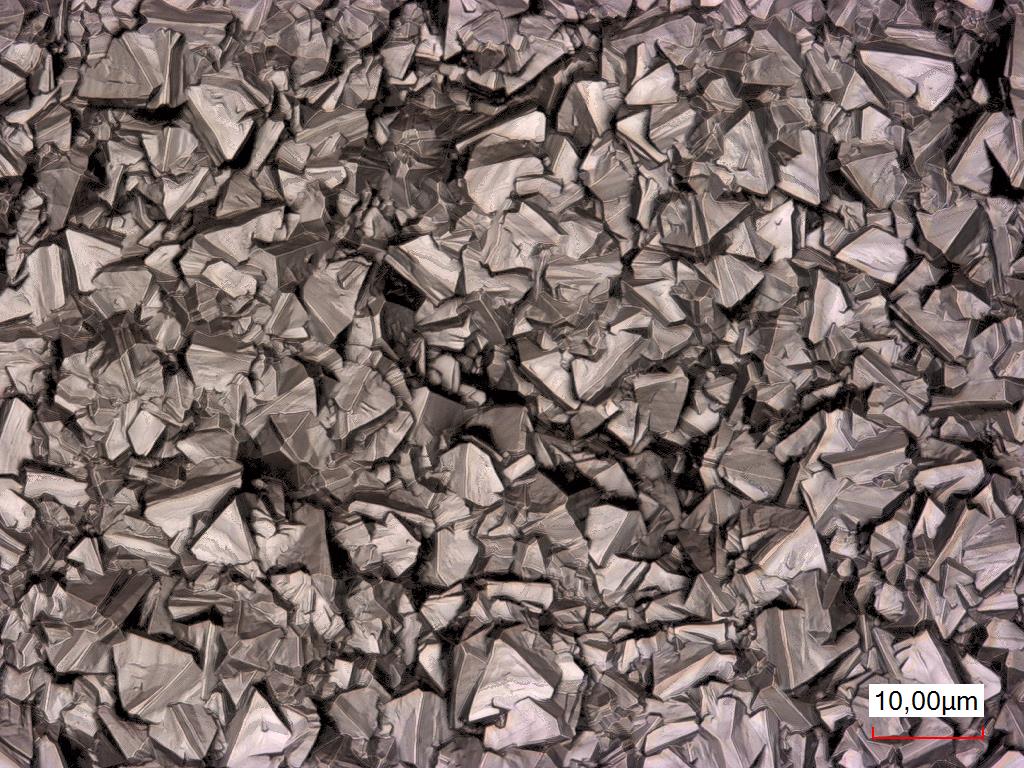

The DIACHEM® electrode, one of the technological core elements of the electrolyser unit, has been custom designed in cooperation with HYPER partner EUT and has been produced by CONDIAS. The process involved several pretreatment steps to prepare a suitable metal-based substrate for HF-CVD coating. Onto the substrate the conductive and highly chemically resistant boron-doped diamond (BDD) coating was applied in CONDIAS’ proprietary HF-CVD systems. The finished DIACHEM® electrode has been provided to EUT, where it will be integrated as anode into the prototype electrolysis cell, that – like the DIACHEM® electrode – has been specifically developed for the HYPER project. Due to the unique electrochemical properties of the DIACHEM® electrode, it will serve its purpose in selectively producing persulfate as the first step of the HYPER-process for sustainable H2O2 production.

The image is an LSM-shot (Laser Scanning Microscope) of the electrodes diamond layer. To the human eye the electrode appears to be mat-black in colour.