On June 5, a highly productive meeting took place between representatives from the National Institute of Chemistry (NIC), the Jožef Stefan Institute (JSI), and industrial partners from Belinka Perkemija, focusing on the ongoing project HYPER. The discussions centred on the current status of project activities and future plans for progress.

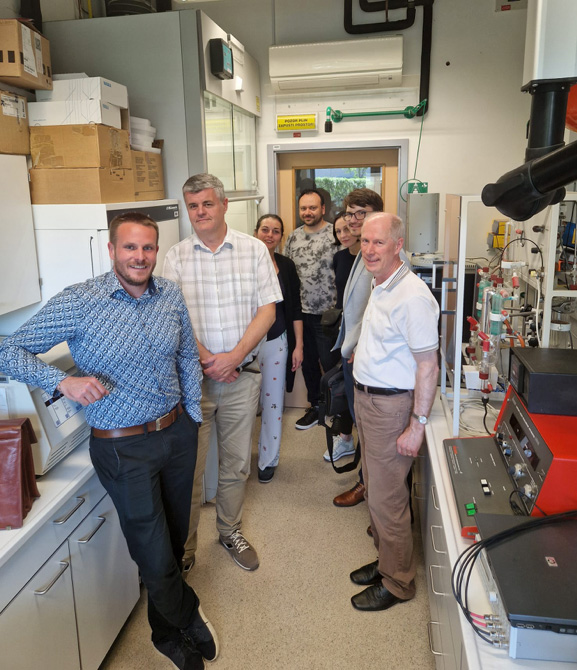

The meeting also included a laboratory tour, showcasing sophisticated equipment for electrolysis, hydrolysis, and downstream processes crucial for the successful execution of the experimental phases of the Hyper Project. This collaboration underscores the strong synergy between research institutions and industry, driving innovative solutions for hydrogen peroxide production.

The Hyper Project aims to pioneer an efficient electrochemical method for producing hydrogen peroxide from persulfates. This innovative process commences with the electrochemical formation of persulfates, which are then hydrolysed to convert them into hydrogen peroxide. The resulting peroxide is subsequently separated and concentrated to meet industrial specifications.

Extensive laboratory tests, conducted by the NIC and IJS research groups, have yielded promising results. Initial experiments utilized commercial sodium persulfate and sulfuric acid for hydrolysis. Following this, an electrolysis cell was established and operated to produce persulfate electrochemically, seamlessly integrating the entire process.

The research then advanced to hydrolysing the electrochemically produced persulfate solution, leading to the development and proposal of additional downstream processes. The gathered experimental data is crucial in constructing a descriptive mathematical model. This model not only predicts outcomes under various reaction conditions but also aids in scaling up the process for industrial applications.

From the left side of the picture: Matija Mencinger (BP – Belinka Perkemija), Gregor Dolanc (JSI), Emina Kapić (NIC), Darko Horvat (BP), Darja Koklič (BP), Andrej Podkoritnik (BP), Janko Petrovčič (JSI)